Resources

Cast Iron [Australian Antique Trader]

Ken Arnold of Crown Castleton Publishers

29 June 2012

[from article in Australian Antique Trader, originally published June 1989 - see below for more information]

INTRODUCTION

With the advent of the Industrial Revolution in Britain great manufacturing centres were established which enabled a revolution in the technique of making things. New production methods afforded artists and designers a chance to produce iron casting which afforded a whole new industry.

Although a charcoal furnace had been in existence from 1638 at Coalbrookdale, Shropshire, England it was not until Abraham Darby moved there in 1709 that it was adopted to smelt iron ore with coke. This small furnace was the beginning of the cast iron industry. Not all coal was satisfactory hence it was replaced by charcoal.

By the 18th century cast iron was popular which saw the steam engine employed for the greater reduction of ore producing a more manageable molten slag. This gave the inventors and designers a wider scope to produce items. As a result new roads and canals were established to transport coal to the manufacturing centres which in turn resulted in greater efficiency and economy.

By the turn of the century an increasing proportion of the population were enjoying a higher standard of living. The higher social status employed servants which commanded that the simple divisions of the family home now required rather more complex rooms. Ceilings were lowered, rooms plastered or panelled with the large open hearth fire places giving way to smaller hearths and grates which in turn saw more chimneys and flues. It was probably a quirk of fate as dry wood was rapidly dwindling to such a state that only coal was available to heat the house. It was at this time that we saw the demise of the andirons (firedogs). They were replaced with a grate within the hearth, however this produced volumes of smoke making life rather unpleasant. Fireplaces became even smaller but this did not reduce the smoke problem. All types of ducting systems were devised until the stove was invented.

By the turn of the century an increasing proportion of the population were enjoying a higher standard of living. The higher social status employed servants which commanded that the simple divisions of the family home now required rather more complex rooms. Ceilings were lowered, rooms plastered or panelled with the large open hearth fire places giving way to smaller hearths and grates which in turn saw more chimneys and flues. It was probably a quirk of fate as dry wood was rapidly dwindling to such a state that only coal was available to heat the house. It was at this time that we saw the demise of the andirons (firedogs). They were replaced with a grate within the hearth, however this produced volumes of smoke making life rather unpleasant. Fireplaces became even smaller but this did not reduce the smoke problem. All types of ducting systems were devised until the stove was invented.

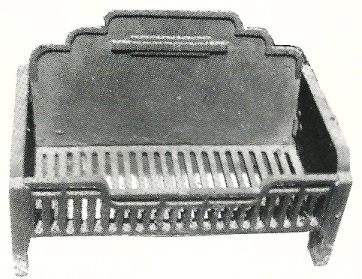

In an attempt to control and concentrate the draught the basket grate was built into the fireplace. These did little to enhance the beauty of the room so they were soon replaced by the hob grate, which allowed for the cast iron kettle or saucepan to be sat on a swivel plate. These grates consumed coal and wood rapidly because there was no draught control. Smoke was still a problem but it could be controlled by a flue in the chimney which drew the smoke away from the room. Many of the larger residences maintained a large fireplace in which a fire back could be installed. Although fairly plain, from 1830-60 they gradually became ornate.

With the radical improvements in casting techniques there was no way in which the heating experts could prevent the inevitable loss of heat through absorption by the black cast iron. Whilst it would have greatly shortened the time required to boil the kettle or heat the saucepan the cast iron firebacks must have directed much wanted heat up the chimney.

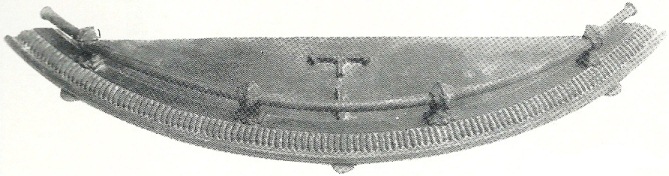

Although most grates had small bars to prevent coals and ash from falling out, a curb or fender was also necessary to prevent damage to the carpet. Curbs should not be confused with a fender. The latter were supplied with or without a base whereas a curb had no base. These were made in a variety of styles and designs.

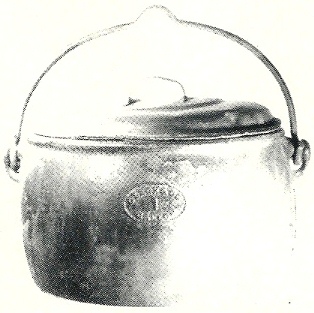

Prior to the flat bottomed heating pots most cooking was done in round bottomed three legged cauldrons which could be sat in the coals or suspended by a crane over the flames. But as the fireplace became smaller it was necessary to get more pots into a smaller area, hence flat bottomed devices, which could be sat in the coals or on the hobs, were invented.

As the population of England was gradually moving into the towns the social areas began to develop. As a result houses evolved accordingly. These urban dwellings now became taller houses with the kitchen often in the basement. This did not curtail the movement of the callers. Many of these terraced houses often had an area provided outside the basement kitchen window to allow air and light to filter into the room. To prevent the passing traffic from falling into this area a cast iron fence was essential.

On reaching the front door a caller was confronted with an array of cast iron objects.

To prevent one from damaging their knuckles on the solid wooden door a cast iron door knocker was installed. A most impressive range of knockers was offered to decorate the Victorian or Edwardian door, mostly produced by Archibald Kenrick, established 1791. Although it has not been confirmed it is thought that there was little competition to this firm as few knockers were marked. These sold from five to fifteen pence (4-13 cents) even in 1840. As these knockers were portable many residents took them from house to house or discarded them in favour of the latest designs. Some of the patterns we are likely to see include lions head, cherubs heads, annulets or simple patterns. It was not until they were readily accepted that the more fashionable bolder designs of animals, birds, flowers, grapes, horseshoes or the familiar ovals and circles were marketed.

With the advent of the penny post of 1840 by Rowland Hill door knockers became incorporated with the letter box plate. These plates were usually fairly flat, however some are ornate.

No front door was complete without a cast iron door knob. These 19th century knobs were usually situated in the centre of the door. These immediately became popular as residents no longer had to pull the door shut by the knocker or spring loaded letter plate, often with devastating damage to the fmgers. These knobs came in a range of sizes and designs.

Before entering the house one would have to remove all the mud, grime and other undesirable material from their footware as most of the roads and the unsanitary conditions left much to be desired. The foot scraper was certainly an essential item so that the rubbish would not be deposited on the carpets or polished floor boards. There were three types of scrapers: Those which were fitted into a recess in the wall were not practical as the shoe could catch on the wall thus scratching the leather while at the best of times not cleaning the shoe properly.

Before entering the house one would have to remove all the mud, grime and other undesirable material from their footware as most of the roads and the unsanitary conditions left much to be desired. The foot scraper was certainly an essential item so that the rubbish would not be deposited on the carpets or polished floor boards. There were three types of scrapers: Those which were fitted into a recess in the wall were not practical as the shoe could catch on the wall thus scratching the leather while at the best of times not cleaning the shoe properly.

Those which fitted into the stone pavement were much better as the shoe could be cleaned without any hassels.

The portable scraper and pan. This popular scraper came in a range of designs however they met their demise when the road and sanitary conditions improved after the turn of the century. With the introduction of the motor car, scrapers almost became a thing of the past at the front door. However they were still employed at the back door to remove the mud after a visit to the outhouse, clothes line or vegetable garden. By the 1940's these scrapers had been replaced with coiled or coconut mats.

No passage would be complete without a door porter. Ranging in size and design, these cast iron door stops have been seen in animals, national heroes, unicorns, Punch and Judy, birds, as well as the usual intricate designs. Those who could not afford a door porter were content to use a house brick wrapped in a cloth, a flat iron or a piece of cast iron.

With the advent of semi detached dwellings and electricity the new fancy chromium plated steel door adornments could jazz up the appearance of the house. Soon the four panel door was fitted with shiny letter plates, press bell and combination lock. However the cast iron labour saving devices within the house stood the test of time until recent times when they gave way to all electric or gas kitchen. It is still possible to meet people who rely on their trusty cast iron wares, and although cast iron ware is almost a thing of our past it is still possible to purchase new items in this media.

This very important part of our social and domestic history is all but passed in a time when our technological changes are rapidly accelerating.

Photographs (from top to bottom):

- (Left) Cast iron hearth.

- (Right) Cast iron Chimney Flue from Stove.

- (Centred) Cast iron curved fender.

- (Left) Cast iron boiler, 13 sizes to 14 gallons.

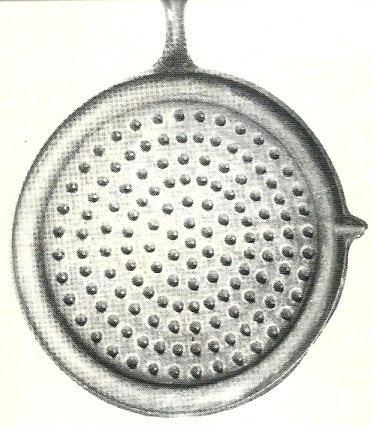

- (Middle) Cast iron Tallow Pan for melting candle wax.

- (Right) Cast iron double handled pot.

- (Left) Cast iron boot scraper.

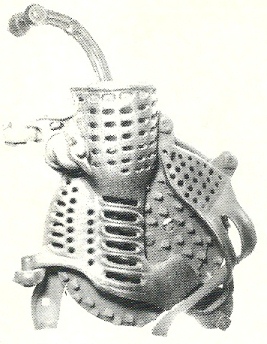

- (Left) Cast iron corncobber.

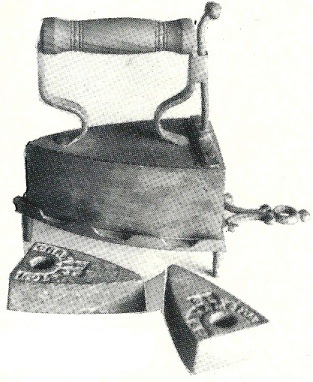

- (Middle) Cast iron clothing iron, Isaac Wilkinson type design.

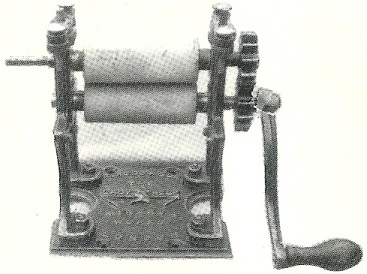

- (Right) Cast iron Minerva works / the Lady Help Knife cleaner, rare item.

----------

[PDF of original article with photographs, 883 kB]

This article is one of a number of articles we thought were of interest on a range of topics that we will be placing on our web site over the coming months. It is taken from the Australian Antique Trader magazine 15th June - 15th July 1989. This article is reproduced with permission of the publisher of the Australian Antique Trader magazine, Alan Carter. Our thanks to Alan for allowing us to place it on to our web site as an information service to our customers.